On very hot days you need more air conditioning capacity to satisfy the heating load demand. The demand put on your home in the summer. In milder weather, you do not need to run the air conditioner at 100% to satisfy the higher demand. HVAC equipment manufacturers have introduced systems that have the ability to run in two stages so that on the hotter days you can satisfy the demand and on the cooler days you can run the system at a lower setting thereby using less energy.

On very hot days you need more air conditioning capacity to satisfy the heating load demand. The demand put on your home in the summer. In milder weather, you do not need to run the air conditioner at 100% to satisfy the higher demand. HVAC equipment manufacturers have introduced systems that have the ability to run in two stages so that on the hotter days you can satisfy the demand and on the cooler days you can run the system at a lower setting thereby using less energy.

Using less energy is the objective so how do we do this? The solution is two-fold for having an efficient running system. One is to reduce the heat gain by insulating the home. Additionally, adding things to the home such as attic fans.

These things help reduce heat gain to the living areas that you want to condition with cool less humid air. The second thing you can do is to purchase a higher efficient system. One that can modulate or offers staging. Staging from a high-level for a higher demand to a lower level for lower demand.

Variable Speed ECM Condenser Fan Motors - Efficiency

HVAC Manufacturers introduced two-stage compressors. There are also modulating compressors that will run according to the demand. The demand is based on exactly what you need to condition your space.

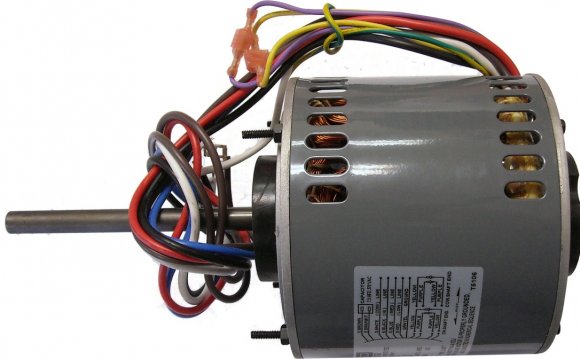

Since the compressor would stage based on the demand they needed a condenser fan motor that would also stage based on demand. Some manufacturers use a standard PSC multi-speed fan motor while others use an ECM fan motor.

These motors facilitate a higher speed for the increased demand. When the system is calling for higher demand the fan needs to run faster. And lower speeds when the system is calling for a lower demand. So when the compressor is running at a higher speed the condenser fan motor will also run at a high speed. When the compressor is running at a lower speed the fan motor will run at a lower speed.

Variable Speed ECM Condenser Fan Motors - Troubleshooting Tips

The ECM condenser fan motor is hooked to an electronic control module. The wires from the motor are hooked up to this control module. The control module for ECM condenser fan motor is preprogrammed at the factory. This is done for the particular motor for a particular function based on the program inside the control module. The parameters for the program are likely based on several different things. Things such as head pressure and the outdoor ambient temperature along with run-time of the condenser.

Manufacturers have diagnostic tools for the ECM motors. Typically you have to unplug the wires going to the control module or at the control module and plug in the diagnostic tool to troubleshoot the ECM. It is a good idea not to pull on the wires but to disconnect the Molex plug carefully so you don’t pull the wires out of the Molex plug. The all you do is follow the instructions for the diagnostic tool you have hooked up. Some are rudimentary and some are advanced and will tell you what the problem is if any.

The rudimentary diagnostic tools for the ECM motors will have a flashing light. It will flash so many times to give you a code. You must have or know the code for however many flashes you get to tell you if something is wrong or that everything is good to go. The chart for the code is usually available at the dealer that sold you or gave you the diagnostic tool for troubleshooting the ECM motor.

Variable Speed ECM Condenser Fan Motors - Additional Tips

- Of course safety first! Make sure you disconnect the power before working with the control module or the ECM motor.

- Always follow the manufacturer’s instructions. This means actually reading the instructions even if you have done it before. Things change and you need to make yourself aware of the changes. Following manufacturer’s service bulletins is difficult even for the best technicians (inside joke for someone I know))).

- Always make sure you have the properly rated voltage for main power. The ECM control module and the motor are sensitive to power issues.

- Always make sure the unit is properly grounded. Follow the grounding out. Check all the way back to the breaker panel if necessary to make sure everything is properly grounded. Electronic devices such as the ECM control module, especially electronic devices that convert AC to DC and the DC power are very sensitive to grounding issues.