Supply and exhaust fans working in cooperation

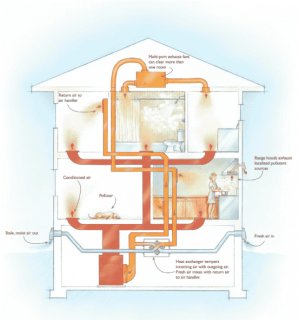

Balanced systems typically have two fans and two duct systems, one for supply air and one for exhaust air. Ductwork can be extensive, with supply ducts to provide fresh air to bedrooms and living areas and exhaust ducts to remove stale air from bathrooms, laundry rooms, and sometimes kitchens.

See below for:

Avoid flex duct if possible

The best duct material for ventilation supply ducts is galvanized steel; flex duct should be avoided or minimized. Some installers use PVC pipe for exhaust ducts.

Design Notes

ENERGY-RECOVERY VENTILATORS (ERVs) work much like heat-recovery ventilators (HRVs), transferring heat between outgoing and incoming ventilation air to reduce heating or cooling loads. The ERV has the added ability to transfer moisture from one air stream to the other.

Heat recovery systems do a better job

While ASHRAE 62.2A standard for residential mechanical ventilation systems established by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers. Among other requirements, the standard requires a home to have a mechanical ventilation system capable of ventilating at a rate of 1 cfm for every 100 square feet of occupiable space plus 7.5 cfm per occupant. ventilation requirements can be met with an exhaust-only or supply-only ventilation system, the performance of these lower-cost ventilation systems will not equal the performance of a properly installed HRV.

Among other requirements, the standard requires a home to have a mechanical ventilation system capable of ventilating at a rate of 1 cfm for every 100 square feet of occupiable space plus 7.5 cfm per occupant. ventilation requirements can be met with an exhaust-only or supply-only ventilation system, the performance of these lower-cost ventilation systems will not equal the performance of a properly installed HRV.

- Compared to an exhaust-only system, a heat-recovery ventilation(HRV). Balanced ventilation system in which most of the heat from outgoing exhaust air is transferred to incoming fresh air via an air-to-air heat exchanger; a similar device, an energy-recovery ventilator, also transfers water vapor. HRVs recover 50% to 80% of the heat in exhausted air. In hot climates, the function is reversed so that the cooler inside air reduces the temperature of the incoming hot air. system will do a better job delivering fresh air to bedrooms.

- Compared to a supply-only system, a heat-recovery ventilation system will usually have a lower operating cost and will do a better job removing odors.

- The energy penalty associated with a heat-recovery ventilation system will be lower than that of any other type of ventilation.

Getting the most out of an HRV

If the budget allows, HRV installations should always include dedicated ventilation ductwork. Such systems are routinely installed in New England homes with hydronic heating systems. Ventilation ducts usually measure 4 inches in diameter. Because air flows and pressures are much lower than those encountered in a forced-air heating system, meticulous duct sealing is essential.

Homes equipped with an HRV do not need bathroom exhaust fans, since the HRV draws its exhaust air from bathrooms and laundry rooms. Each bathroom can be equipped with an override switch to operate the HRV at high speed for odor removal. An HRV should never pull exhaust air from a range hood, since grease can clog an HRV.

When an HRV is installed in a home with a furnace, the existing forced-air ductwork is usually used for the mechanical ventilation system. Although such systems work, they involve technical compromises that may degrade the performance and energy efficiency of the HRV. Forced-air ductwork is much larger than necessary to handle the needs of a ventilation system. If the HRV is wired to use the furnace blower motor to distribute ventilation air, energy use will be much higher than it would be if the HRV fans were used.