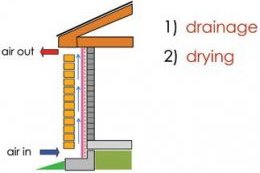

As designers and building owners place increased demands on exterior walls to isolate the outside climate from the interior controlled environment, exterior walls’ capability to provide long-term assured performance must grow. As building enclosure design evolves, it is becoming more evident that important attributes of durable exterior cavity walls, in wet climates, must include the ability of the exterior wall to drain and dry quickly to protect the wall assembly from moisture-related issues.

As designers and building owners place increased demands on exterior walls to isolate the outside climate from the interior controlled environment, exterior walls’ capability to provide long-term assured performance must grow. As building enclosure design evolves, it is becoming more evident that important attributes of durable exterior cavity walls, in wet climates, must include the ability of the exterior wall to drain and dry quickly to protect the wall assembly from moisture-related issues.

CAVITY WALL EVOLUTION

Historically, exterior masonry walls managed water by utilizing an abundance of mass to absorb moisture from the environment and then release it back slowly by random drainage and evaporation when the exterior relative humidity allowed. Typically, bulk water did not reach interior surfaces of thick mass walls due to the multiple masonry wythes, each with their inherent high moisture-storage capacity. Additionally, the drying efficiency of uninsulated mass-masonry walls is aided by the passage of interior energy out through the mass.

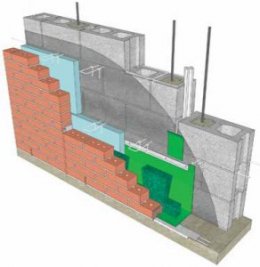

Today, thick mass masonry walls have been replaced with thin, energy-efficient and economical masonry cavity wall construction with internal water and air barriers, continuous insulation, and air space between the structural support wall and the exterior veneer. This modern wall assembly has isolated the veneer to experience more thermal and material movement, moisture-related stresses, and staining potential than massive masonry walls. Adding to the challenge of designing durable exterior wall systems, structural masonry support walls are sometimes replaced with moisture-sensitive materials such as wood and other sheathing products and associated framing. All these factors make rapid drainage and drying of exterior wall systems even more vital.

Adding to the challenge of designing durable exterior wall systems, structural masonry support walls are sometimes replaced with moisture-sensitive materials such as wood and other sheathing products and associated framing. All these factors make rapid drainage and drying of exterior wall systems even more vital.

CAVITY WALL TYPES

Today there are three main types of cavity wall design:

- Unventilated

- Pressure-equalized

- Ventilated

UNVENTILATED CAVITY WALLS

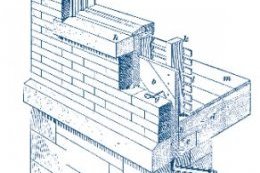

The roots of modern cavity wall design can be traced back to the late 1800s, when wall systems started to become less massive, due to better material strength, improved understanding of the system, and a desire to reduce material cost, increase speed of construction, and minimize thermal and moisture transfer across the wall. For nearly 100 years, unventilated cavity walls were the norm until the mid to late 1900s, when building designers started to experiment with alternative design strategies to refine moisture, staining, and energy management methods for cavity walls by introducing upgraded wall assembly components and advanced moisture control design strategies such as pressure-equalized rainscreen wall concepts.

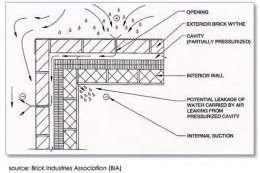

PRESSURE-EQUALIZED CAVITY WALLS

In theory, pressure-equalized rainscreen walls are designed to allow enough exterior air into the wall cavity to create back pressure to reduce or eliminate the positive force of wind-driven rain against the veneer. However, in reality, there are too many variables required in order for a system to be designed and installed flawlessly and achieve a true net-zero pressure differential across a veneer. To achieve a pressure-equalized rainscreen wall, the wall design needs to address:

However, in reality, there are too many variables required in order for a system to be designed and installed flawlessly and achieve a true net-zero pressure differential across a veneer. To achieve a pressure-equalized rainscreen wall, the wall design needs to address:

- The rigidity of the support wall

- Actual air barrier continuity and tightness

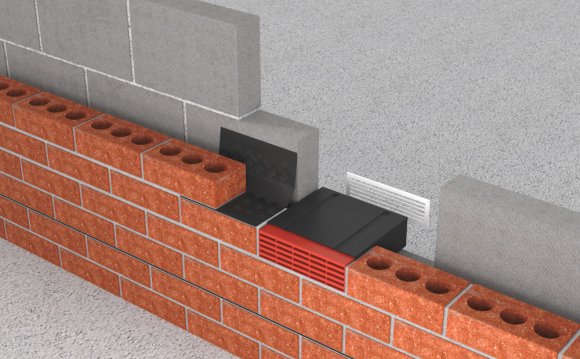

- The weep vent type/spacing/location in the wall

- A weep-vent-free area of venting

- Increased modern air space recommendations

- Wall cavity baffle airtightness

- Mortar droppings

- Landscaping mulch

- Overall workmanship

Pressure-equalized rainscreen walls can be achieved, but not without proper calculations, design, quality control, instrumental verification, and skilled craftworkers. Because of the complexity of pressure-equalized rainscreen walls and the high level of wall assembly coordination required, it is ideal to have one contractor install the entire exterior wall assembly for single-source responsibility.

We would suggest student housing newcastle no agency fees.

VENTILATED CAVITY WALLS

A more realistic and economical approach for increased moisture management in exterior cavity walls is the use of a ventilated cavity wall concept. Ventilated cavity walls use some similar components of pressure-equalized rainscreen walls, but without the calculations, small air space chamber requirements, observation, testing, and related cost. In fact, some building scientists have stated that many, if not most, pressure-equalized rainscreen walls are not properly designed or executed and are just functioning as “well-ventilated cavity walls, ” anyway.

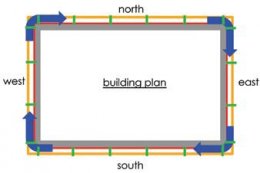

A ventilated cavity wall works on the simple premise of letting air into and out of the wall cavity through weep vents strategically located both low and high in veneer panels to connect the internal wall cavity with the exterior environment. This connection promotes drying of the wall assembly as moisture is dissipated to the exterior through vents in the veneer. Venting of the wall cavity in wet climates creates walls that are more resilient with less moisture-related issues such as spalling, cracking, or staining. In some cases, the introduction of wall cavity venting to an existing unventilated cavity wall has helped alleviate or eliminate chronic efflorescence, since salt-saturated moisture does not have time to form in abundance or migrate to the surface of the veneer.